Ear Savers

One of the largest-scale projects across North America, Asia, and Europe involved solving an equipment problem that largely didn’t exist before the pandemic. The standard for healthcare workers changed in that they needed to wear masks at all times, which applied prolonged pressure to the backs of their ears.

Those in retail, grocery, and other essential services felt an even worse transition as they began wearing masks when they hadn’t before.

Enter stage EARSAVERS

Standard Saver

This is the form most people are accustomed to when discussing 3D printed ear savers. They are designed to attach to both loops of a surgical-style mask and hold the tension from the back of the head. Most design photos will show these worn above the occipital bone section of the head, though in everyday wear some people have worn them on the back of their neck.

This design is homemade and was my first attempt at making material-efficient and comfortable equipment.

One additional feature of the standard design was customizability, such as the addition of logos and colour changes to match the group of volunteers who would wear the ear savers.

This feature largely went unused as the initial outflow of ear savers were for hospitals and volume was the main concern.

Though we attempted to donate ear savers to local high schools and teachers, we had issues getting responses from staff in school management. A handful of customized ear savers were distributed casually to teachers who were aware of the project.

Modular Ear Saver v1

The next hurdle was alleviating stress from the top and bottom surfaces of the ear cartilage. The solution we found was to print a larger ear saver, similar to the standard design, but with a taller profile to tension the mask loops around the ear.

As we printed the larger savers, we found our 3D printers could print two savers at a time on a single bed. For comparison, we could squeeze 7-8 standard ear savers on a single bed depending on the printer. In decreasing our amount of product per print, we had to either lower upcoming order quantities or spend more time each day resetting the printers.

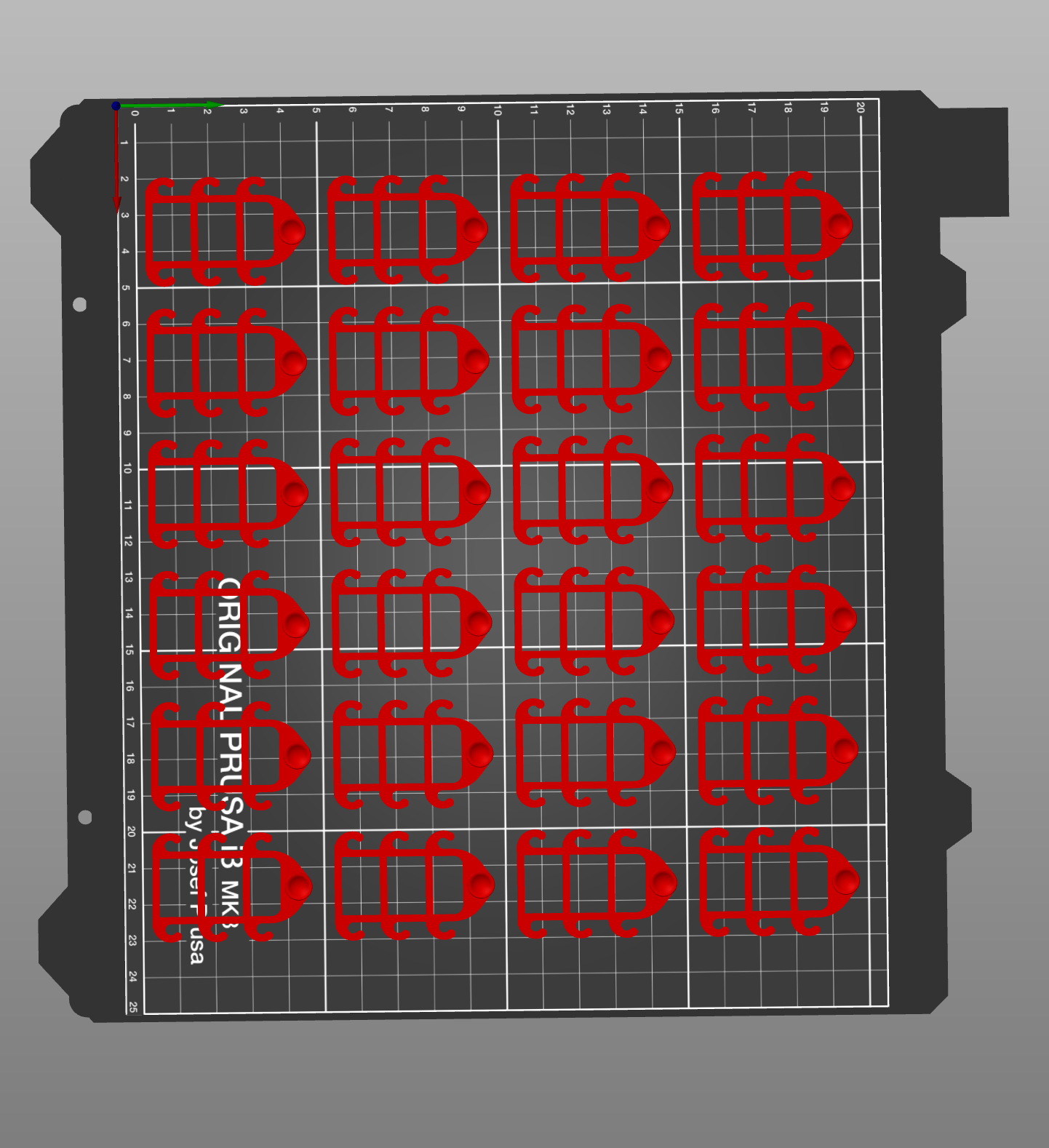

The modular design concept was meant to split a single large ear saver into four thin pieces which could be printed in larger batches and pieced together by the wearer. One issue with this design was the tension applied on each end causing the parts to “unbutton” where the central connectors would dislodge. A simple solution would be to affix the parts using a stapler or pressing a soldering iron through the connection sites.

Modular Ear Saver v2

One of the final design iterations was inspired by the local hospital staff who faced difficulties from their religious needs. A Sikh nurse reached out and asked for a longer version of the standard ear saver design. In designing a lengthened version, issues of bed space and design complexity began to pop up.

The extra-long plastic ear saver was an unrealistic solution, and looking at the design it became apparent the majority of the issues came from the sheer length of the ear saver body.

At the same time, we had been producing visors that required elastic straps to hold the visor up. The combination of the two, elastic strap and saver, would open up ear savers to complete customization for the end-user.

Recreating the ends of the former ear savers allow for fine control of mask loop tension- while using a button-style attachment means an elastic strap of any length can make up the main body.

By decreasing the overall plastic needed per person and print size on a 3D printer bed, more savers were produced with each print and more individuals could be served with a single spool of filament.

The donated savers were a success and the local hospital staff without access to their ears or wearing religious garments were able to don and doff their masks with ease.

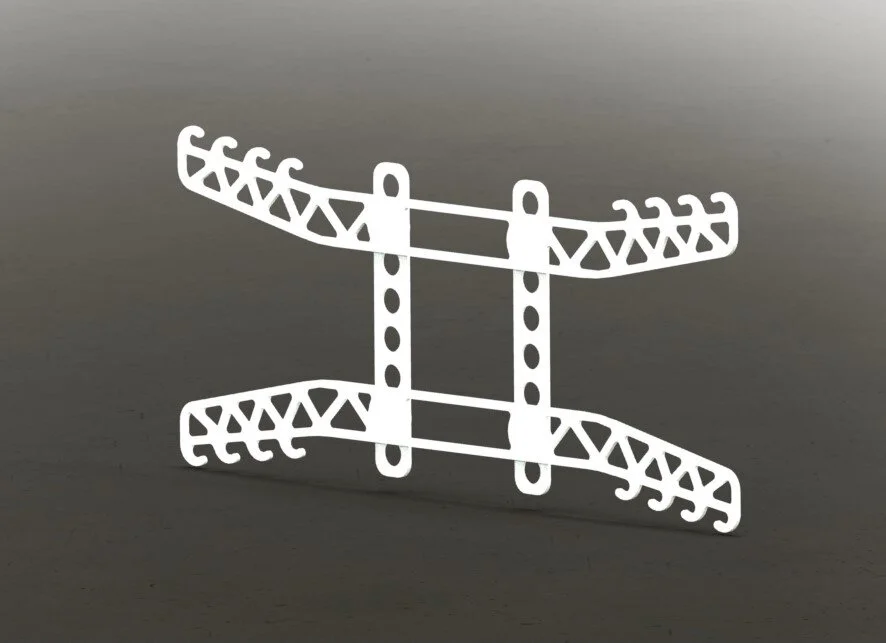

The final iteration of the modular ear saver added curvature to the mask attachment site, allowing the ear saver to get within close proximity of the wearer’s ear without the mask touching their ear. This design is intended for those whose mask loops are too tight for the standard ear saver or former button-style modular design.

Though this design uses less filament and wasn’t an issue for the printers we used, we reached the end of our project distributing PPE to the local community and had no need to produce more en-masse.

The modular ear savers are now produced on an as-needed basis; if you or your community would benefit from this equipment please feel free to reach out.